Pumps - Thermoplastic &

Metallic

Warrender Pumps

Zero Leakage - Zero Corrosion™ Our mag-drive pumps can run your proces ses free of leakage, contamination or toxic spillage. Avoid potential environmental fines and constant monitoring. Eliminate toxic and dangerous chemical releases- even when handling volatile, explosive or environmentally reactive chemicals--by operating 100% leakfree. WARRENDER mag-drive pumps are constructed of a wide variety of materials to satisfy specific process requirements for chemical inertia, corrosion and temperature resistance.

Molded Thermoplastic, Horizontal

WMCP molded horizontal centrifugal seal-less mag-drive thermoplastic pumps (superseding the M) provide high reliability, with emphasis on optimum chemical compatibility. Interchangeable impellers provide flexibility for precisely matching head and flow capacities. WMCP Molded Horizontal pumps can be used in a wide range of acids and alkaline solutions up to temperatures of 180°F.

FEATURES

- Heavy walled casings for added strength, pressure and temperature resistance

- Volute casing for optimum efficiencies and performances

- Interchangeable impellers, independent of internal magnets

- High torque, low mass magnetic couplings resist uncoupling

- Oversized internal shaft, sleeve and thrust bearings

- Standard 56-C & 143-TC NEMA frame motors

TECHNICAL DATA

- Flow: 2-175 GPM (.45-40 Mł/H)

- Head: To 110 F (33 M)

- Temp: To 180°F (85°C)

- System Pressures: 50 PSIG (3 Bar)

MATERIALS:

- PP, PVDF

Molded Thermoplastic, Vertical

WMCP molded vertical centrifugal seal-less mag-drive thermoplastic pumps (superseding the MV) are engineered for reliability, durability and chemical resistance. Molded vertical pumps are best suited for filtration and spray systems, intank and sump applications. Complete isolation of the motor from the process liquid prevents internal corrosion, air entrainment or product contamination. Zero-leakage operation ensures maximum safety and full compliance with toxic emissions regulations.

FEATURES

- Heavy walled casings for added strength, pressure and temperature resistance

- Volute casing for optimum efficiencies and performances

- Interchangeable impellers, independent of internal magnets

- High torque, low mass magnetic couplings resist uncoupling

- Oversized internal shaft, sleeve and thrust bearings

- Standard 56-C & 143-TC NEMA frame motors

- Quick-change rear cartridge assembly allows ease of servicing and reduces maintenance costs

- High-torque magnetic couplings eliminate need for soft-starting motors

- All ports are raised-face 150 lb. or 300 lb. ANSI flanges (600 lb. and 900 lb. are also available)

TECHNICAL DATA

- Flow: 2-175 GPM (.45-40 Mł/H)

- Head: To 110 F (33 M)

- Temp: To 180°F (85°C)

- System Pressures: 50 PSIG (3 Bar)

MATERIALS:

- PP, PVDF

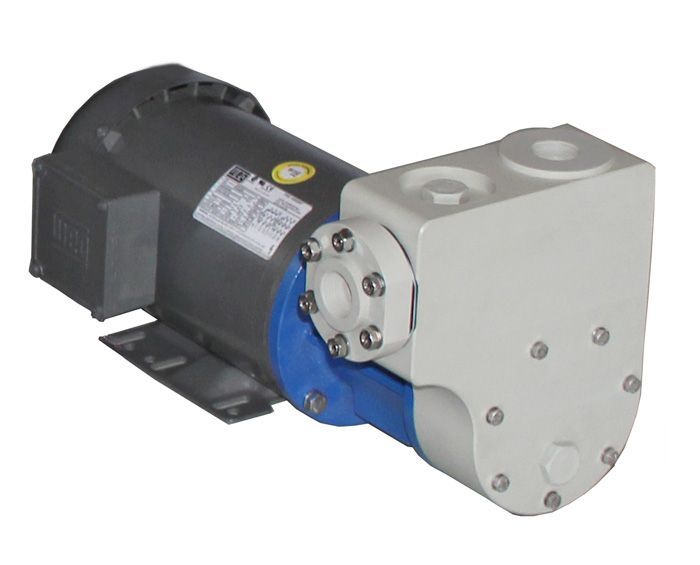

Machined Thermoplastic, Horizontal

WMCP machined thermoplastic horizontal centrifugal seal-less mag-drive pumps (superseding the MCH) are fabricated from SOLID Simona ® PP or PVDF thermoplastics to resist internal or external corrosion. Heavy walled, CNC machined construction provide far greater resistance to permeation and migration of corrosive, and permeating liquids. Additionally, added strength and thermal stability resists deformation, even in the most severe applications.

FEATURES

- Exclusive SOLID machined PP or PVDF casings and impeller components for maximum chemical resistance

- All plastic casing withstands external corrosion

- Integral raised face flanges (no threaded adapters) to ensure zero leakage

- Modular impeller allows for varying hydraulic performances

- Oversized, high purity ceramic or silicon carbide thrust bearings and shaft

- Standard, direct starting NEMA motors

TECHNICAL DATA

- Flow: 3-500 GPM (.68-113 Mł/H)

- Head: To 175 F (53 M)

- Temp: To 200°F (95°C)

- System Pressures: 100 PSIG (7 Bar)

MATERIALS:

- PP, PVDF

Machined Thermoplastic, Self Siphoning

WMTP machined thermoplastic regenerative turbine seal-less mag-drive Pumps (superseding the MT) Ideally suited to low flow applications, WMTP regenerative turbine pumps avoid oversized centrifugals, that require flow by-passing and excessive horsepower. WMTP non-metallic turbine designs have excellent chemical resistance and extremely low wear characteristics. Variation in head calculations have minimal effect on the flow of a turbine pump. Also, turbine pumps can be throttled to a required duty point without by-passing.

FEATURES

- Exclusive solid machined PP or PVDF casings and impeller components

- Heavy casing wall thicknesses

- Resists external corrosion

- Self-balancing impeller eliminates thrust bearing wear

- Handles up to 20% entrained gas, resists cavitation

- Direct starting, standard NEMA motors

TECHNICAL DATA

- Flow: 0.6-65 GPM (0.13-13Mł/H)

- Head: 180 Feet (55 M)

- Temp: To 200°F (95°C)

- System Pressures: 100 PSIG (7 Bar)

MATERIALS:

- PP, PVDF, ETFE

Machined Thermoplastic, Self-Priming

WMTP machined thermoplastic self-priming regenerative turbine seal-less mag-drive pumps (superseding the MT-SP) provide smooth, continuous, leak-proof operation where top unloading is required. The same basic features of Self- Siphoning pumps apply to The Self-Priming series design with the addition of a self-contained, self-priming pump casing.

FEATURES

- Exclusive solid machined PP or PVDF casings and impeller components

- Self-Priming pump housing

- Resists external corrosion

- Self-balancing impeller eliminates thrust bearing wear

- Handles up to 20% entrained gas, resists cavitation

- Direct starting, standard NEMA motors

TECHNICAL DATA

- Flow: 0.60-55 GPM (0.13-13 Mł/H)

- Head: To 180 F (55 M)

- Temp: To 200°F (95°C)

- System Pressures: 100 PSIG (7 Bar)

MATERIALS:

- PP, PVDF, ETFE

Machined Thermoplastic, Horizontal Self-Priming

WMCP machined thermoplastic self-priming centrifugal seal-less mag-drive pumps (superseding the MT-SP) apply to the Self-Priming design with the addition of a self-contained, self-priming pump casing. Machined Horizontal Self-Priming pumps provide smooth continuous leak-proof operation where top unloading is specified.

FEATURES

- Exclusive SOLID machined PP or PVDF casings and impeller components for maximum chemical resistance

- All plastic casing withstands external corrosion

- Integral raised face flanges (no threaded adapters) to ensure zero leakage

- Modular impeller allows for varying hydraulic performances

- Oversized, high purity ceramic or silicon carbide thrust bearings and shaft

- Standard, direct starting NEMA motors

TECHNICAL DATA

- Flow: 30-275 GPM (5.8-62 Mł/H)

- Head: To 130 F (40 M)

- Temp: To 200°F (95°C)

- System Pressures: 100 PSIG (7 Bar)

MATERIALS:

- PP, PVDF, ETFE

Machined Thermoplastic, In-Line

WMRP machined thermoplastic self-priming rotary vane seal-less mag-drive pumps (superseding the MP) are positive displacement pumps intended for low-flow/high head applications, high-pressure systems or where metering is required. CNC machined from solid Simona polypropylene or polyvinylidene fluoride (PVDF), WMRP Machined In-Line pumps are extremely resistance to internal or external corrosion, permeation and migration of solvents and corrosive. WMRP Machined In-Line pumps can handle pressurized applications and are capable of dry starting. Zero-leakage operation ensures maximum safety and full compliance with toxic emissions regulations.

FEATURES

- Self-Priming and can run dry without damage

- No gears to wear or metal to metal contact, low internal slip

- Capable of proportioning with variable speed drives, turn-down ratios depend upon differential head

- requirements

- Replaceable carbon cartridge-low maintenanace costs

- High torque magnets for direct starting motors

- All non-metallic wetted components

TECHNICAL DATA

- Flow: .1-11 GPM (22-2500 Mł/H)

- Head: To 50 psig (3.4 bar)

- Temp: To 200°F (to 95°C)

- System Pressures: 180 PSIG (7 Bar)

MATERIALS:

- PP, PVDF, ETFE

Metallic Pumps

Machined Metallic Billet, In-Line Port

The WARRENDER WMRA Machined Billet Rotary Vane Seal-Less Mag-drive Pumps (superseding the WMDAV) are built for high system pressures and special alloy requirements. All WMRA pumps are equipped with zero leakage magnetic couplings to meet the latest toxic emissions regulations. The absence of mechanical seals eliminates costly pump maintenance, lost production time and process contamination. The WMRA pumps feature self-compensating sliding-vanes which maintain design head and flow capacities for extended operating life. The WMRA pumps are suitable for thin nonlubricating liquids and/or high differential pressures. The WMRA pumps are capable of dry self-priming.

FEATURES

- Self-priming and can run dry without damage

- No gears to wear or metal to metal contact, low internal slip

- Capable of proportioning with variable speed drives, turn-down ratios depend upon differential head

- requirements

- Heavy duty alloy containment shell for added safety

- Replaceable carbon cartridge-low maintenance costs

- High Torque magnets for direct starting motors

TECHNICAL DATA

- Flow: .1-11 GPM (22-2500 Mł/H)

- Head: To 180 psig (12 bar)

- Temp: To 450°F (to 232°C)

- System Pressures: 7250 PSIG (500 Bar)

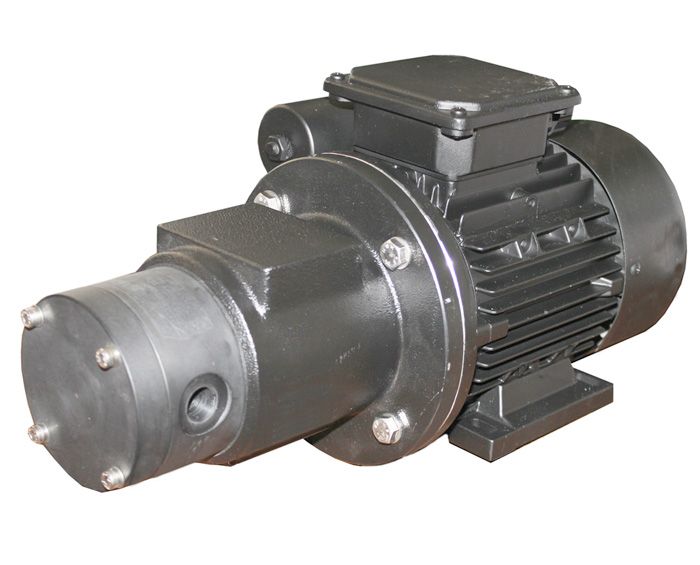

Compact Metallic Horizontal, End Suction

WARRENDER WMCA alloy compact centrifugal mag-drive pumps (superseding the ST) provide the advantages of a heavyduty seal-less process pump in a compact, cost effective design. WMCA Horizontal pumps are equipped with zero leakage magnetic couplings to meet the latest toxic emissions regulations. The absence of mechanical seals eliminates costly pump maintenance, lost production time and process contamination.

FEATURES

- Seal-less magnetic drive coupling

- Rugged alloy casing and pump components

- Heavy duty alloy containment shell

- High efficiency enclosed impeller design

- High torque magnets suitable for direct starting motors

- Close-coupled NEMA motor frame or bearing pedestal

TECHNICAL DATA

- Flow: 5-150 GPM (1.1-34 Mł/H)

- Head: To 115 F (35 M)

- Temp: -148 to 450°F (-100 to 232°C)

- System Pressures: 150 PSIG (10 Bar)

MATERIALS:

- SS-316 stainless steel, Hastelloy-C276

Cast, Single Stage

WMTA alloy regenerative turbine seal-less mag-drive pumps (superseding the WMDAT) are ideally suited for low flow/High Head Applications. All WMTA pumps are equipped with zero leakage magnetic couplings to meet the latest toxic emissions regulations. The absence of mechanical seals or packing glands eliminates costly pump maintenance, lost production time and process contamination. The WMTA pumps are able to pump liquids containing up to 20% entrained gas. The WMTA pumps are suitable for thick non-lubricating liquids and/or high differential pressures.

FEATURES

- High head/low flow capability minimizes by-pass requirements and prevents overheating of centrifugals and

- high head cavitation

- Self balancing impeller-Zero axial thrust loading

- Impeller design handles up to 20% entrained gas-ideal for pumping liquefied gases

- No galling or metal to metal contact

- Heavy duty alloy containment shell

- High torque magnets, suitable for direct starting motors

TECHNICAL DATA

- Flow: .25-55 GPM (.5-10 Mł/H)

- Head: To 700 F (213 M)

- Temp: -148 to 600°F (-100 to 316°C)

- System Pressures: 700 PSIG (48 Bar)

MATERIALS:

- AISI SS-316 Stainless Steel, Alloy-20, Incoloy-825, Hastelloy-C27